History of Workplace Safety

A look at over 200 years of safety developments in the workplace

From Coal Mines to Cloud Monitoring: The Evolution of Workplace Safety and Lone Worker Protection

Looking back at the past is key to creating a safer future. While current workplaces can absolutely benefit from digital lone worker solutions and automated check-in systems, it’s also important to recognize the long journey that brought us here. Reading further, this article will explore more than 200 years of workplace safety evolution – from the Industrial Revolution to modern, real-time lone worker monitoring – highlighting the OHS advancements and why continued innovation matters.

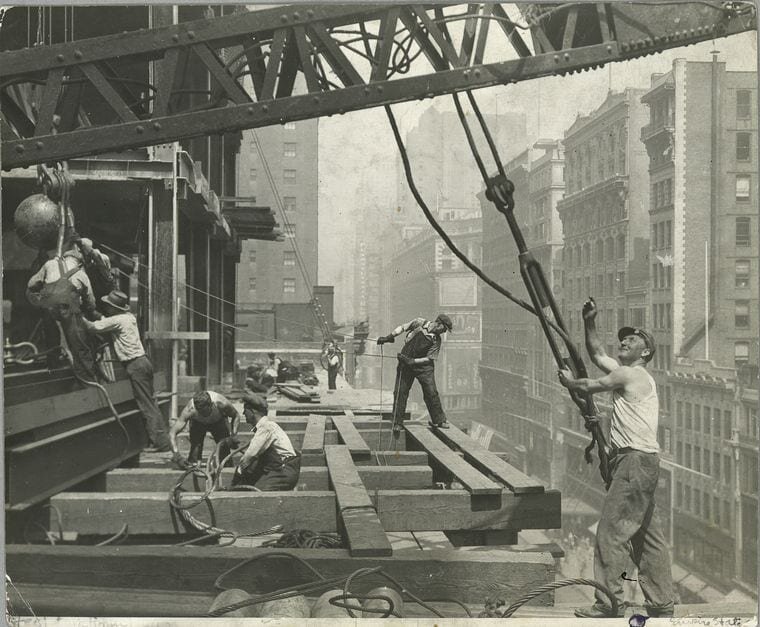

The Industrial Revolution: where safety assessment and awareness began

Workplace safety first found its roots during Europe’s Industrial Revolution. As new rapidly industries grew, so did the safety risks within them. Workers created unions to demand safety working conditions, prompting governments to introduce safety regulations. This sets out the early groundwork for industry-specific safety standards that continue to evolve and protect workers to this day.

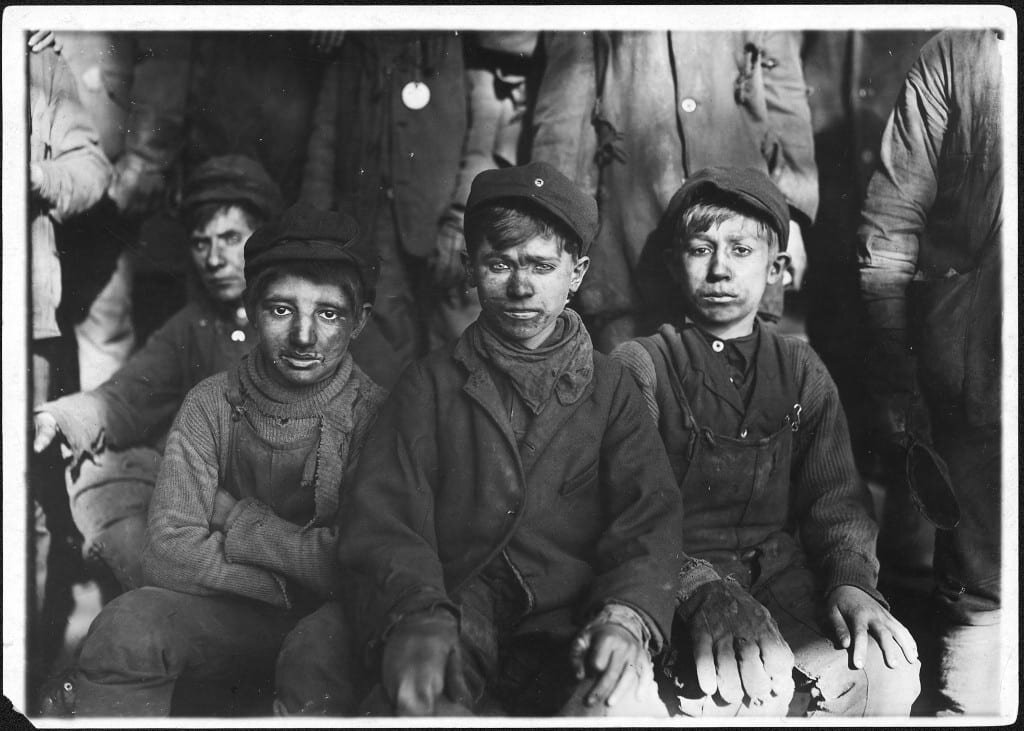

Mining: A dangerous start to industrial labor

Mining for minerals and metals was one of the earliest and most hazardous industries. By the late 1600s, shaft mining was growing because of advancements in steam-powered pumps. The 1770s brought automation like more efficient engines and lower fuel costs, causing mining to be more profitable – and also more dangerous for workers.

Miners, who also included young children, faced workplace hazards such as collapsing tunnels, toxic gases, and frequent explosions. The invention of the safety lamp in 1815 helped reduce the hazard of dangerous gas ignition risks. Later on, new safety technologies including electric lighting and battery-powered lamps also improved workplace safety, noting the beginning of technology-driven worker protection.

Factories and manufacturing: the creation of safety legislation

When manufacturing moved workers into factories, new kinds of hazards began to present themselves. Factory work at the time meant long hours with poor ventilation and dangerous equipment. In 1784, poor working conditions cause a fever outbreak among cotton mill workers in the United Kingdom. This eventually led to the Health and Morals of Apprentices Act in 1802. The act required factories to provide proper ventilation and clean work spaces. While it was not regularly enforced, this act set a precedent for factory acts that followed.

Factories and manufacturing: the creation of safety legislation

Men standing on an open train. SOURCE: WIKIPEDIA

Early trains and rail systems were built weak. Even though they were much slower than today’s rail systems, they were very dangerous. Common injuries and fatalities in the railroad industry included boiler explosions and train wrecks. Making matters worse, railroad bridges often weren’t strong enough to support their load. This lead to occasional collapses as trains crossed. Poor braking systems and heavy loads meant stopping could be difficult. In the United States, heavy traffic on single-track lines made collisions common. Workers operated hand brakes on top of cars, leading to many deaths during train wrecks. In 1851-52, 28 percent of fatalities reported in New York were the result of falls from trains. Poor safety records became an increasing concern for the railroad. By the 1870s, air brakes became standard equipment on most passenger trains. Freight trains followed in 1881. In 1893, these new developments produced the United States’ Federal Safety Appliance Act. The act mandated air brakes, automated couplers, and handholds on all railroad cars carrying freight.

Agriculture: from biological hazards to heavy machinery

Working on a farm around the turn of the century. SOURCE: WIKIPEDIA

Agricultural workers historically dealt with infectious diseases from animal waste, spoiled grain, and particulate matter. When agriculture industrialized, workers faced new dangers from pesticides and mechanized equipment. As science and medicine began to transform agriculture, worker safety was also affected. The study of microbes and diseases helped workers, but advancements also brought other dangers. Chemicals like pesticides were originally only tested for their effectiveness, without concern for workers. Since then, government organizations have now helped label chemicals for toxicity and potential health impacts. Policy improvements in the 20th century eventually led to chemicals being tested for safety.

International acknowledgement of workers’ rights: labor and workers days become recognized

Since the 1890s, Labour Day in Canada and Labor Day in the US have recognized and celebrated workers’ rights every September as an official holiday. For the rest of the world, International Workers’ Day (aka Labour Day as well or May Day) is celebrated every year on May 1, which was ostensibly inspired earlier in 1856 by Australian masons who did mass work stoppage to protest long, unsafe work hours.

The International Labour Organization (ILO): A global safety advocate for workers everywhere

Created as part of the legendary Treaty of Versailles that helped bring World War I to an end, the International Labour Organization (ILO) arose from “security, humanitarian, political and economic considerations.” The ILO Constitution in 1919 by the Labour Commission, chaired by Samuel Gompers, head of the American Federation of Labour (AFL), and was originally made up of representatives from nine countries: Belgium, Cuba, Czechoslovakia, France, Italy, Japan, Poland, the United Kingdom as well as the United States.

Modern safety legislation and regulations: OSHA and CCOHS : The Occupational Health and Safety Act and Administration - US and Canada

In the 70s, governments around the world began to take worker and occupational health and safety much more seriously.

In 1970, the US passes the Occupational Health and Safety (OHS) Act and creates the Occupational Health and Safety Administration (OSHA) to pass, regulate, and maintain health and safety standards and regulations. The OHS Act was created to safety and working conditions for workers regardless of job title and industry.

Eight years later, Canada took similar steps passing an OHS act and forming the Canadian Centre for Occupational Health and Safety (CCOHS). The goals of the CCOHS are “for the advancement of safe and healthy workplaces and preventing work-related injuries, illnesses, and deaths.”

Safety training goes online

In 1992, the OSHA establishes the OSHA Training Institute and then the OSHA Training Institute (OTI) Education Center Program, which trains “Federal and State compliance officers and State consultation program staff, but also provides training for private sector personnel and Federal personnel from agencies other than OSHA on a space available basis.”

Safety training is now the focus and priority of many major safety organizations such:

With the significant advances in technology, safety training can now be completed anytime and anywhere with virtual simulation devices that can replicate almost any scenario in the workplace using sensors, headsets, and controllers. Because of this, safety training has become much more affordable and safer for the participants.

The Digital Revolution: Protecting lone and remote workers

As work environments evolve and shift everywhere, lone workers—employees who work in isolation—face unique workplace hazards and risks. Governments and safety organizations are now realizing and recognizing the special need for digital lone worker solutions that offer:

Real-time remote lone worker monitoring

Proactive safety check-in systems

Automated emergency alerts

GPS satellite tracking and location-based safety protocols

Organizations such SafetyLine Lone Worker are leading the way, using cloud-based platforms and mobile apps on your smartphone to make sure lone workers are never truly disconnected and alone. These innovations in lone worker monitoring represent the next frontier in workplace safety.

OSHA and NIOSH unite to protect lone workers

In a landmark collaboration, OSHA and NIOSH partnered in 2023 to address the growing safety and health challenges faced by lone workers; those who operate without immediate support or supervision. This initiative aims to raise awareness, develop prevention strategies, and improve workplace protections across industries. As lone work becomes more common due to automation and lean staffing, this partnership marked a critical step toward ensuring that every worker, no matter how isolated, has the tools and support needed to stay safe.

Conclusion: A safer future starts with smarter solutions

From work in coal mines to cloud-based monitoring, workplace safety has come a long, long way. As industries move forward and evolve with the times, so must our approach to worker safety—especially those who work alone. By embracing digital lone worker solutions, proactive safety protocols, and continuous safety training, we can build an organization and future where every worker feels secure, connected, and supported.

What Is SafetyLine Lone Worker?

SafetyLine Lone Worker is a cloud-based safety monitoring platform designed to protect employees who work alone, remotely, or in high-risk environments. As workplace safety has evolved from coal mines to digital solutions, SafetyLine represents the modern frontier; offering real-time protection through smart technology.

Features offered by SafetyLine:

Automated Safety Check-Ins: Workers confirm their safety at scheduled intervals, reducing risk and ensuring accountability.

Emergency Alerts and Escalation: If a check-in is missed or a panic button is activated, SafetyLine immediately notifies designated responders.

GPS and Satellite Tracking: Location-based monitoring ensures rapid response in emergencies, even in remote areas.

Fall and No-Motion Detection: Automatically detects incidents where a worker may be incapacitated and triggers alerts.

Custom Safety Instructions: Tailored protocols based on job type, location, or hazard level to guide responders effectively.

Incident Reporting and Analytics: Generates detailed reports for post-incident review, compliance, and continuous safety improvement.

SafetyLine empowers organizations to modernize their safety programs, ensuring that lone workers are never truly alone—even in the most isolated environments.